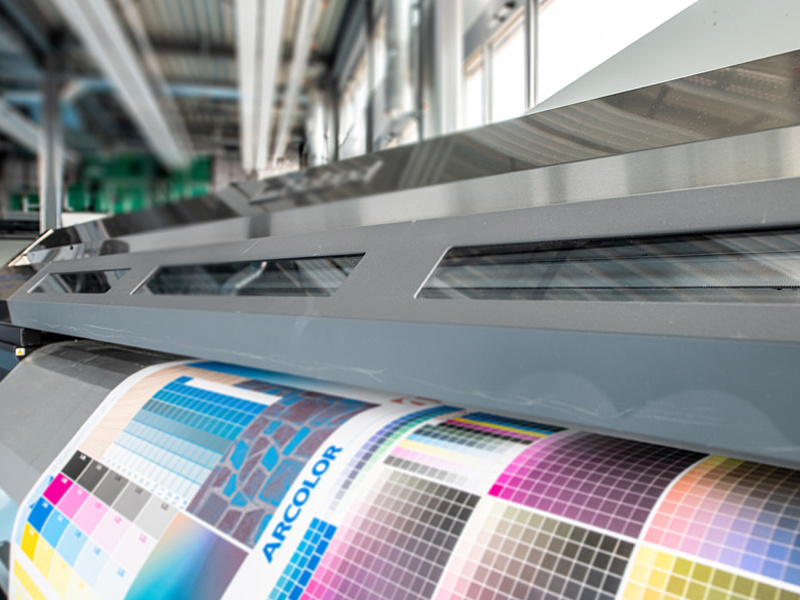

Industry Applications

The remote I/O module of the plastic film extension unit can be connected to sensors and instruments on the printing equipment, such as temperature sensors, humidity sensors, color detectors, etc., to collect various data in real-time during the printing process. These data can be transmitted to the data analysis system through remote I/O modules for data analysis and modeling to optimize printing processes, improve product quality and consistency. The remote I/O module can be connected to energy consumption monitoring instruments and environmental monitoring equipment to collect real-time energy consumption data and environmental parameters during the printing process. Through remote I/O modules, operators can remotely monitor energy consumption and environmental conditions, conduct energy-saving and environmental management, and reduce resource consumption and environmental pollution. Through production monitoring and scheduling, equipment control and management, data collection and analysis, quality management and testing, as well as energy-saving and environmental monitoring functions, remote I/O modules can improve the efficiency, quality, and sustainable development level of printing production.

Project Application

| entry name | product | number |

| Printing equipment | Remote I/O module | *** |

| Roller flexographic printing machine | Remote I/O module | *** |

| Big four open four color business printing machine | Remote I/O module | *** |

| Silicone screen printing machine | Remote I/O module | *** |

| Silicone screen printing plastic film extension machine | Remote I/O module | *** |

Address: Floor 12~13, Building 2, No.28 Dongcun Road, Jiangning District, Nanjing

Telephone:86-25-87187408/87187418

WeChat Consulting

©2023 Nanjing Paragon Technology Co., Ltd. Technical Support:China Enterprise Power Nanjing SEO Tags

©2023 NANJING PARAGON TECHNOLOGY CO., LTD

Technical Support:China Enterprise Power Nanjing SEO Tags

Business License